CITRUS® Ecosystem

The industrial energy demand represents approximately a third of the world total energy consumption and is predominantly powered by fossil fuels. Technological advancements in renewable energy technologies are rapidly changing the dynamics within the industrial landscape, thus presenting great opportunities of the way energy is being generated and consumed.

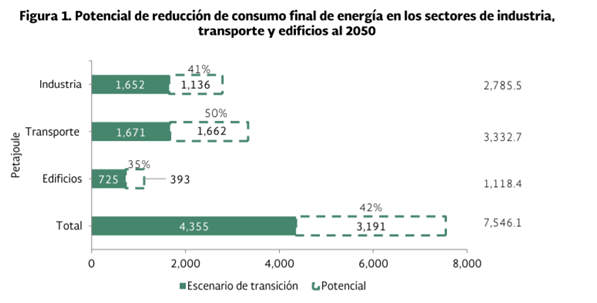

As illustrated in the following chart from SENER and CONUEE reports, it is estimated that such improvements will have the potential to reduce the overall industrial energy consumption by 41% by 2050. Conclusively, the companies taking the necessary steps addressing this opportunity by optimizing its energy generation & use are likely to gain a critical competitive advantage and more importantly, to sustain growth. Afterall, only by ensuring your energy requirements are being met, are you able to grow.

CITRUS Industrial Solutions

The Ecosystem and its applications

The CITRUS Ecosystem – turning your vision into reality

ILLUSTRATIVE CASE STUDY: a dairy company

To drive further growth and address emerging challenges in the business landscape, the company has decided to take a surgical look into its operations, starting with its energy management. Their facilities are equipped with a SCADA monitoring system to control the vital parameters in the operations and a natural gas boiler is providing steam to the processes. The institution decides to apply the CITRUS Ecosystem as the solution to meet its operational objectives and illustrated as follows:

Optimize

Thanks to the monitoring system, the engineer in charge of pasteurization reported unusual low steam temperatures at the heat exchanger input in milk processing. However, the maintenance service cannot explain the origin of the problem.

CITRUS CHECK-UP – The objective of the check-up is to identify vulnerabilities and causes of identified problems. This is achieved, using specialized measuring equipment and analyzing the actual operational conditions and energy supply.

Having measured the inputs, outputs of the process and boiler, an energy balance was established. The analysis showed reduced efficiency in the steam generation due to low maintenance of the boiler. Failures in the distribution system were also detected using IR cameras. Leakages and hot points showing inefficient insulation leading to further thermal losses and reduced temperatures in process.

The CITRUS CHECK-UP Report identified the various issues but also the solutions with associated costs, benefits and ROI for each alternative. This corporate radiography of the operations identifies the causes of operational inefficiencies and its treatment.

The benefits of the Check-up were the following:

- Operational Assessement similar to a radiography, the actual operational pains and inefficiencies were identified.

- Decision Making, the findings outlined the potential solutions with the associated analysis, enabling the organization to effectively prioritize the required actions and activities to address its operational inefficiencies.

- Energy Management, with the actual energy balance including relevant KPIs from generation, distribution to points of use, the company is now able to assess the results of all corrective measures made. Ensuring that its energy infrastructure and operations will support the projected future growth objectives

Chapter 2: learn about how a dairy company transformed its energy generation…

*This illustration presenting a dairy company is for educational purposes only, aiming to present the application of the CITRUS Ecosystem®.